The Importance of Stainless Steel Wire Mesh in Filtration Systems

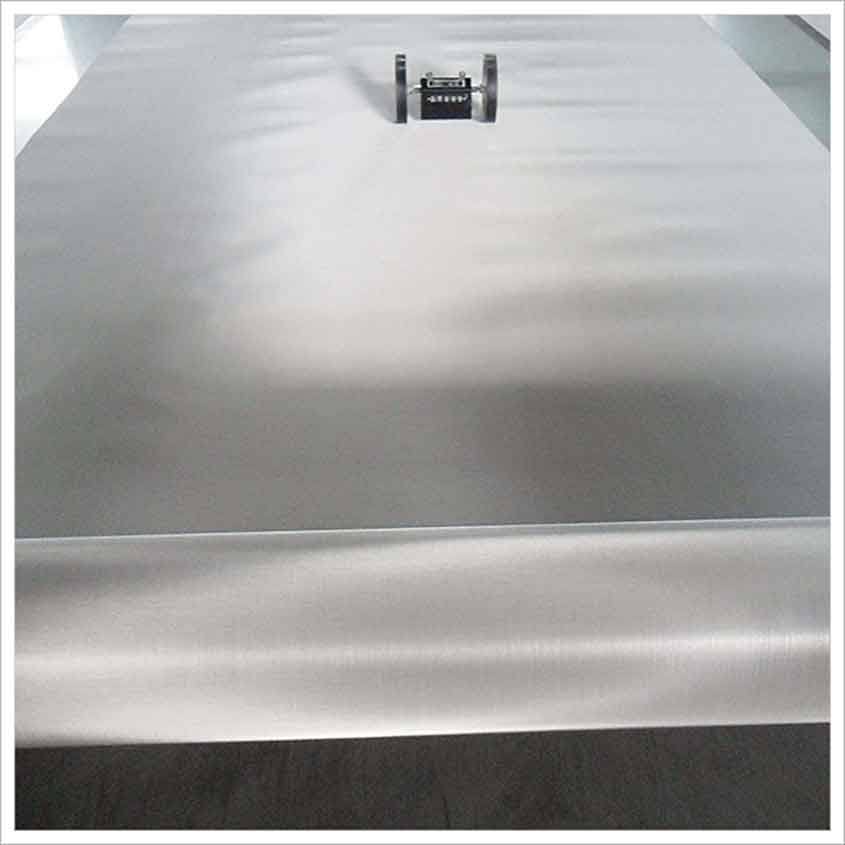

Among these filtration systems, stainless steel wire mesh stands out as an excellent choice due to its exceptional corrosion resistance, high strength, and fine filtering capabilities. This article delves into the significance of stainless steel wire mesh in filtration systems, highlighting its advantages and relevance in achieving efficient and reliable filtration processes.

Introduction:

Filtration systems are essential in a wide range of applications, including water treatment, oil and gas refining, pharmaceutical production, food processing, and many more. They are designed to separate unwanted contaminants from fluids or gases, ensuring that the end product meets stringent quality standards. Within these filtration systems, the use of stainless steel wire mesh has proven to be a critical factor in achieving optimal filtration efficiency and longevity.

Corrosion Resistance:

One of the primary reasons for the widespread adoption of stainless steel wire mesh in filtration systems is its remarkable corrosion resistance. Stainless steel is inherently resistant to rust and degradation caused by exposure to various substances, including chemicals, acids, and saline environments. This property allows the wire mesh to maintain its integrity and effectiveness over extended periods, even in harsh operating conditions.

High Strength and Durability:

Stainless steel wire mesh is renowned for its exceptional strength and durability. As filtration systems often encounter high pressures and mechanical stresses during operation, using a robust material like stainless steel ensures that the mesh can withstand these challenges without deformation or failure. This durability leads to reduced maintenance requirements and prolonged service life, making it a cost-effective solution in the long run.

-

Best Chain Link Fence for Security Applications Feb 10, 2026

Best Chain Link Fence for Security Applications Feb 10, 2026 Best Welded Wire Mesh for South American Markets Feb 03, 2026

Best Welded Wire Mesh for South American Markets Feb 03, 2026 Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026 How to Check the Quality of Welded Wire Mesh Jan 16, 2026

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: 8618032412189

- Add.: No.69 The Filter Industrial Part of Anping, Hebei, China